Valvɔ ƒe kadodo ƒe anyigba ƒe wɔwɔme kpɔa ŋusẽ ɖe valvɔ ƒe nutrenu ƒe dɔwɔwɔ, eɖoɖo mɔnu kple kakaɖedzi le pɔmpi ƒe ɖoɖo me dzi tẽ.TWSaƒo nu tso kadodomɔnu veviwo kple woƒe nɔnɔmewo ŋu kpuie le nyati sia me.

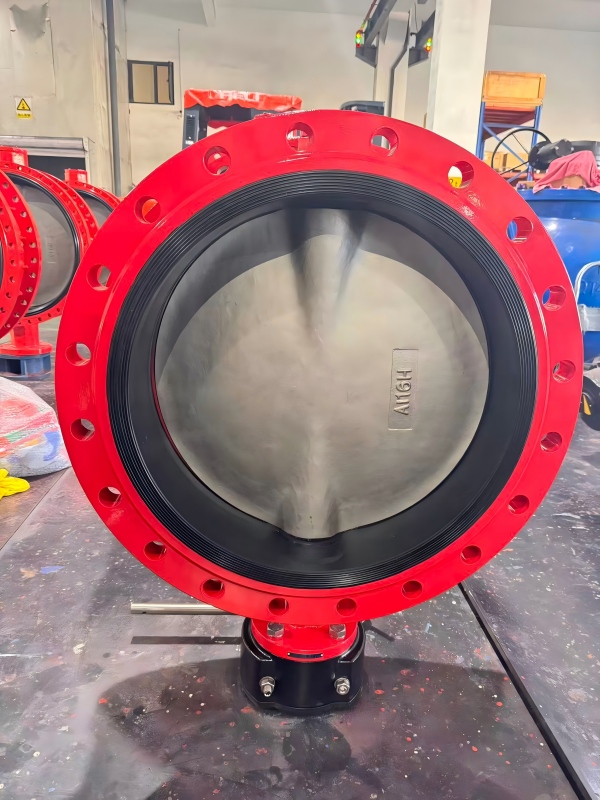

Xexeame katã ƒe kadodomɔnua ɖoa nutrenu to bolted fastening of paired flanges me.

Nutrenu ƒe anyigba ƒomevi siwo bɔ:

-Anyigba si do go: Aɖaŋu si bɔ wu, kple nutrenu ƒe anyigba si do go 2-3mm, si sɔ na nyaƒoɖeamenu ƒe didime si keke (PN10-PN25).

-Concave-convex anyigba: nutrenu ƒe dɔwɔwɔ nyuie wu, si sɔ na dzobibi kple aɖi nyadzɔdzɔgblɔmɔnuwo.

-Groove anyigba: nutrenu nyuitɔ kekeake, wozãna na nyadzɔdzɔgblɔmɔnuwo si me afɔku le ŋutɔ kple nyaƒoɖeamenu gã nɔnɔmewo.

-Ring kadodo anyigba: Ga ring gasket, wowɔ na nyaƒoɖeamenu gã kple dzoxɔxɔ gã dɔwo. Viɖe siwo le eŋu: Nutrenu si ŋu kakaɖedzi le eye woate ŋu amae bɔbɔe.

Nusiwo gblẽ le eŋu: eƒe lolome kple kpekpeme gã, gazazã gã.

Valvɔa ƒe nɔnɔme menye flanged o, eye wotsɔ gavi didiwo blae ɖe pɔmpi ƒe flangewo dome. Nu vevi siwo ɖe dzesi le eŋu dometɔ aɖewoe nye xɔtunu si le sue, xɔtutu si mebɔbɔ o, kple gazazã nyuie. Gake ebia be woaɖoe ƒe dzidzenu kɔkɔwo eye beléle nɛ sesẽ. Wozãa aɖaŋu sia geɖe le...kpakpaluʋui ƒe ʋuƒokplecheck valves ƒe ʋuƒo.

Threaded connection nye mɔ̃ɖaŋu kadodomɔnu si zãa threaded fasteners tsɔ doa ka kple akpawo eye woate ŋu aɖee ɖa ɣesiaɣi.

Viɖe siwo le nutrenu ŋu: Nusiwo wowɔna le agbɔsɔsɔ gã me nana be ewɔwɔ ƒe gazazãwo mebɔna kura o, si nye kadodomɔnu siwo mexɔa ga geɖe o dometɔ ɖeka.

Nusiwo gblẽ le eŋu: Ele bɔbɔe be woaɖe asi le eŋu le ʋuʋudedi kple agba si wotsɔ ƒoa nui te, eye nuteɖeamedzi si le ka la ƒe ke me nana eƒe ɖeɖiteameŋu ƒe ŋusẽ dzi ɖena kpɔtɔna.

IV. Welding ƒe Kadodowo

Kadodo si nɔa anyi ɖaa si ŋu kakaɖedzi le wu.

-Type: Butt welding: Ŋusẽ gã, tsi tsitretsitsi sue, sɔ na dɔwɔwɔ ƒe nɔnɔme sesẽwo.

-Plug-le welding kadodo: Ele bɔbɔe be woaɖo, sɔ na sue-diameter pɔmpiwo. Viɖe siwo le eŋu: Zero leakage, ʋuʋudedi-tsitretsitsi.

Nusiwo gblẽ le eŋu: 5. Esesẽ be woaɖee ɖa. Kadodo ƒomevi bubuwo: Clamping connections: Wozãnɛ le dzadzɛnyenye dɔwɔƒewo hena dzadzɛnyenye bɔbɔe. Abɔta ƒe kadodowo: Wozãnɛ le dɔwɔnuwo kple hadrolik-mɔ̃wo me.

Tiatiawɔƒewo:

1. Tia mɔnu le nyaƒoɖeamenu kple dzoxɔxɔ nu: nyaƒoɖeamenu gã kple dzoxɔxɔ gã ele be woawɔ welded alo asigɛ kadodo.

2. Wonɔ te ɖe medium ƒe nɔnɔmewo dzi: Le nyadzɔdzɔgblɔmɔ̃ siwo me afɔku le gome la, wokafui be woawɔ welding alo tenon-joint ƒe anyigbawo.

3. Bu eɖoɖo kple beléle nɛ ŋu: Woɖea flange kadodoa ɖa enuenu.

4. Gazazã Kple Teƒe si Woazã: Wafer la mexɔa ga geɖe o eye wònɔa sue.

V. Nyanuwuwuw :

Kadodo nyuitɔ nye nu vevitɔ si ana pɔmpiwo nanɔ dedie ahawɔ dɔ nyuie. Na eŋutinunyalawo ƒe mɔfiame kple hoʋiʋli ƒe nyayɔyɔwo le míaƒekpakpaluʋui ƒe ʋuƒo, agbo ƒe ʋuƒo, kplecheck valves ƒe ʋuƒo. KadodoTWSbe nàke ɖe wò nuhiahiãwo gbɔ kpɔnu deblibo ŋu.

Ɣeyiɣi si woɖoe ɖe amewo: Nov-25-2025